Managing a product lifecycle often means juggling spreadsheets, CAD files, change requests, and email threads. For some teams, this creates constant delays and confusion, while others achieve a clear, connected process that moves ideas smoothly from concept to launch.

What makes the difference? The systems and processes you put in place to manage it all. That’s where Product Lifecycle Management (PLM) comes in.

Whether you’re designing medical devices, consumer goods, or industrial machinery, the way you manage your product data and workflows will shape your company’s ability to innovate, hit launch dates, and protect margins. Without a central system, you risk mistakes, rework, compliance issues, and ballooning costs. With PLM, you create the digital backbone that connects people, processes, and data across the entire product journey.

In this guide, I’ll break down what PLM really means, how it works in practice, who benefits most, and the key factors to keep in mind when choosing a solution. Think of it as your starting point: a high-level foundation that can guide you toward deeper dives on comparisons, implementation steps, and best practices.

What Is PLM?

At its simplest, Product Lifecycle Management (PLM) is a strategic approach—and often a supporting software system—for managing a product through its entire journey: from idea and design, through production and distribution, to service and eventual retirement.

But calling PLM “software” alone undersells it. It’s more like the central nervous system of product development, connecting the many moving parts that influence how quickly and successfully you can bring something to market.

Where tools like ERP handle business transactions and PDM manage design files, PLM bridges the gaps. It unites engineering, manufacturing, supply chain, and quality teams around a single source of truth for product data and processes.

The Key Ingredients of PLM

- Holistic coverage: Tracks the entire lifecycle, not just design or production.

- Data backbone: Manages items, BOMs, documents, and change history in one place.

- Workflow engine: Standardizes processes like new product introduction (NPI) and engineering change orders (ECOs).

- Collaboration hub: Brings cross-functional teams together with clear roles, tasks, and audit trails.

Why It Matters

The power of PLM lies in reducing complexity. By giving everyone—from design engineers to procurement to compliance—a single, reliable view of product information, PLM eliminates silos, speeds up decision-making, and lowers the risk of costly mistakes.

In today’s industries, PLM is less of a “nice-to-have” and more of a competitive requirement. Without it, you’re relying on spreadsheets and scattered systems to do the work of a purpose-built backbone—and that’s when errors, delays, and compliance gaps creep in.

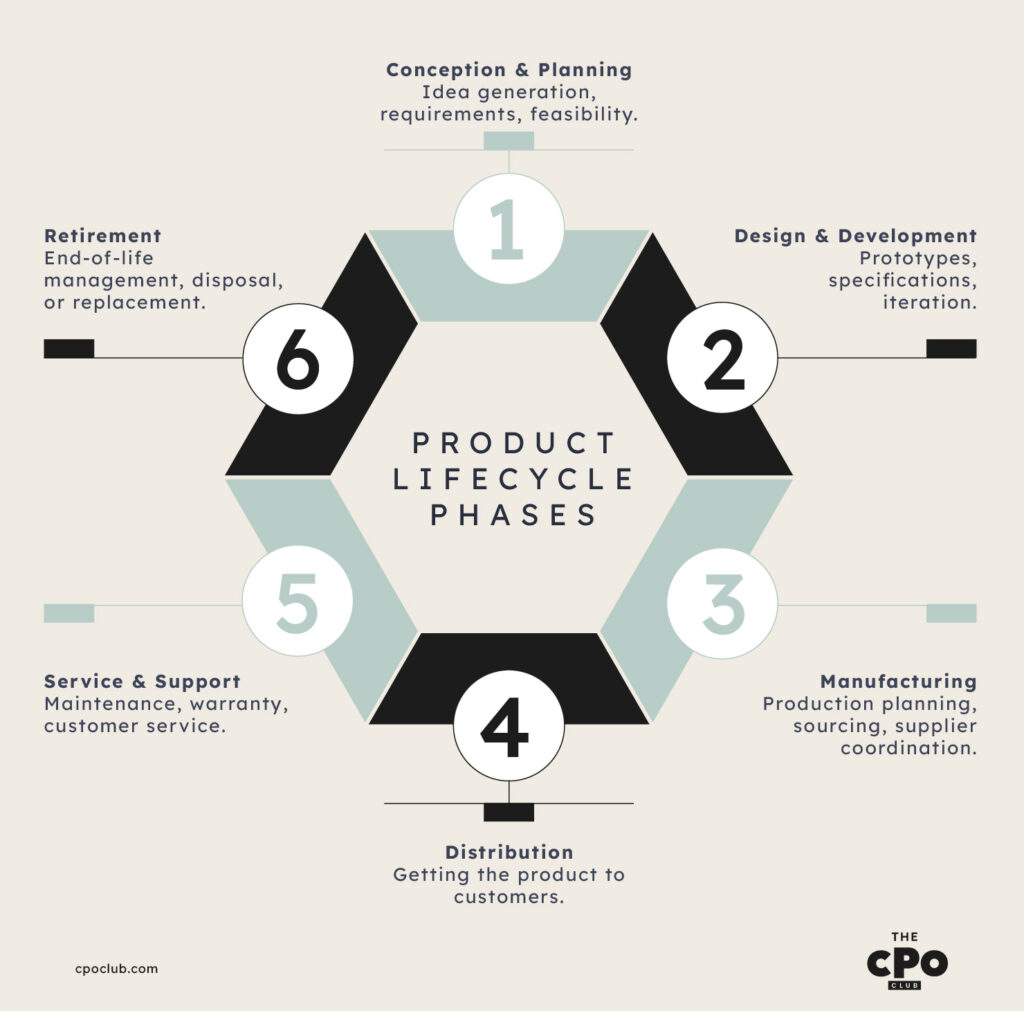

What is The Product Lifecycle?

Before we talk about how PLM works, let’s zoom out and think about the product lifecycle itself. Every product—whether it’s a phone, a snack food, or a piece of heavy equipment—goes through a defined beginning, middle, and end.

If you can’t identify those stages, you’re probably not looking at a “product” in the strict sense but at an ongoing operation.

PLM exists to bring clarity and control to these stages. It’s the framework that ties them together, so no stage exists in isolation.

Why Is PLM Important?

It can be tempting to view PLM as “extra” work—just another system to learn or another layer of process when deadlines are already tight. But skipping it almost always comes back to bite you.

Think about it: without PLM, product data lives in silos—marketing has their version of the specs, engineering has another, and suppliers may be working from outdated files. The result? Missed launch dates, blown budgets, compliance headaches, and frustrated teams.

I’ve seen organizations try to manage complex products with nothing but spreadsheets and email. In the short term, it feels fast. But over time, the problems pile up: version confusion, costly rework, recalls, and lost customer trust.

Once you’ve experienced those pain points, PLM stops feeling optional and starts looking like insurance against chaos. When implemented well, PLM builds confidence—across stakeholders, regulators, suppliers, and customers—that you know exactly what’s happening with your product and where it’s headed next.

How Does PLM Work?

Think of PLM as the digital backbone of your product development process. Instead of relying on scattered tools—spreadsheets here, CAD files there, ERP over in finance—PLM pulls everything together into one connected system.

It doesn’t replace those other tools, but it does something critical: it makes sure they talk to each other and that everyone works from the same playbook.

Here’s what that looks like in practice:

- Data Centralization: All product-related information—parts, designs, documents, bills of materials (BOMs), change requests—lives in one place. This creates a single source of truth, so teams aren’t second-guessing which file or version to trust.

- Workflow Orchestration: PLM isn’t just storage—it’s the engine that runs your processes. Need to release a new product? The system walks you through stage-gates. Need to make an engineering change? It routes approvals, tracks redlines, and logs the impact.

- Cross-Functional Collaboration: Engineers, procurement, manufacturing, quality, and even suppliers can work within the same platform. Instead of endless email chains, everyone sees the same updated data and knows who’s responsible for what.

- Integration with Other Systems: PLM sits between CAD/PDM systems (where designs are created) and ERP/MES systems (where production and operations live). It ensures that once a product is designed, the right data flows downstream into manufacturing, purchasing, and finance.

- Traceability & Control: Every change, decision, and document is tracked. That means you have an audit trail for compliance, plus the ability to trace a defect or issue back to its root cause without sifting through guesswork.

Who Should Use PLM (and Why)

In every company I’ve seen—whether building smart home gadgets or specialty foods—product data and decisions are spread across people, systems, and geographies. That disconnect creates handoff delays, miscommunication, and costly mistakes.

PLM bridges that gap, embedding structure and transparency across teams, roles, and stages. Here's who stands to gain the most:

| Team / Role | Current Challenge | How PLM Helps |

|---|---|---|

| Engineering / Design | Version confusion, rework, missed changes | Dashboards on cycle time, costs, and quality metrics |

| Product Management | Slow forecasting, unclear roadmap | Single source of truth for planning, dependencies |

| Supply Chain & Procurement | Late orders, supplier misalignment | BOM management, early supplier collaboration |

| Manufacturing & Operations | Out-of-sync production, misbuilt designs | Real-time BOM sync, workflows for approvals |

| Quality / Regulatory | Audit gaps, non-compliance risk | Audit trails, compliance tagging, traceability |

| Service & Support | Delayed service docs, unknown components | Unified component history and documentation |

| Executive Leadership | Slow launches, lack of product visibility | Dashboards on cycle time, costs, quality metrics |

Types of PLM Tools

Another big question: what tools should you actually use for product lifecycle management? The answer depends a lot on your industry, product type, team size, and budget.

As with any system, the goal is not to overload your teams with complicated software. The right PLM platform should feel like an enabler, not another hurdle. And whichever tool you pick, its value will largely come down to how well it integrates with your existing ecosystem—CAD, ERP, MES, or even project management tools your team already relies on.

Some categories of PLM-related tools to consider:

- Core PLM Platforms – These are the backbone systems (e.g., Arena PLM, Siemens Teamcenter, PTC Windchill, Autodesk Fusion Lifecycle) that centralize product data, manage BOMs, and orchestrate change processes. See our roundup of the best PLM software.

- Requirements Management Tools – To keep product requirements clear, traceable, and aligned with design and manufacturing. You’ll find some overlap with product planning software here.

- CAD / PDM Integrations – Tools that link design files and revisions directly into the PLM system so engineering work stays connected to the rest of the product record.

- Collaboration & Supplier Portals – Modules or add-ons for working with external suppliers, contractors, and distributed teams.

- Quality & Compliance Modules – Often built into PLM, these handle CAPA, audit trails, and regulatory workflows.

- Analytics Dashboards – Tools or extensions that help track KPIs like cycle times, cost of change, and on-time launch rates.

You can also explore more specialized options like Agile PLM software if your workflows demand a more iterative, flexible approach, or dig into our Tiers and Costs guide for specific tools like Roadmunk to understand what implementation really costs.

8 Core Records in a PLM System

When you implement PLM, you’ll rely on a set of standardized product records. These are the backbone of your digital product portfolio, and they define how data flows through every stage of the lifecycle.

The most common records include:

- Item Master: The single record for each part, subassembly, or product—including metadata, numbers, and lifecycle states.

- Bill of Materials (BOM): The hierarchical list of all components and materials required to build a product. PLM manages multiple BOM views (engineering, manufacturing, service).

- Document Management: Specs, CAD drawings, datasheets, and other supporting files tied to the product record.

- Requirements Record: A structured way to capture and trace requirements from market need through design and validation.

- Change Objects (ECO/ECN): Formalized records for proposed and approved engineering changes—complete with approvers, redlines, and impact analysis.

- Quality Records: Issues, CAPAs, test results, and audit trails, often linked directly to product items and changes.

- Project / NPI Templates: Standardized project structures used to guide new product introductions (NPI) through stage gates.

- Portfolio Roadmaps & Dashboards: At the strategic level, PLM data rolls up into portfolio views that help leadership make investment and timing decisions. A portfolio roadmap is essentially a high-level plan that connects product-level detail to business strategy and portfolio management tools can add measurable value by improving prioritization, alignment, and visibility across the entire product suite (see the key benefits here).

While this isn’t an exhaustive list, these records form the core of most PLM platforms. They ensure every stakeholder is looking at the same, up-to-date data—whether that’s a design engineer reviewing CAD revisions, or an exec scanning a dashboard of launch timelines.

PLM Vendor Comparison Checklist

Use this table as a quick reference when evaluating providers—ask each vendor the same set of questions so you can compare apples-to-apples.

| Factor | Why It Matters | Questions to Ask |

|---|---|---|

| Industry Fit | Every industry has unique needs—formulations vs. discrete BOMs, regulatory requirements, etc. | Do you have customers in our industry? Can you show case studies? |

| Integration Depth | PLM must connect to CAD, ERP, MES, QMS. Poor integration = duplicate data & errors. | What CAD/ERP connectors are included? Do you support open APIs? |

| Configurability vs. Customization | Highly customized systems are expensive and hard to upgrade. | What can we configure ourselves vs. needing professional services? |

| Ease of Use | User adoption is everything. A clunky system = low engagement. | Can you demo a typical engineer/procurement task in under 5 minutes? |

| Security & Compliance | You’re storing sensitive IP and regulated records—must be airtight. | Do you support audit trails, e-signatures, and industry certifications? |

| Total Cost of Ownership | Licenses are just the start—factor in implementation, training, admin. | What’s included in subscription vs. extra? What’s the 3–5 year TCO? |

| Services & Roadmap | You need a vendor who grows with you, not one you’ll outgrow. | What’s on your product roadmap? How do you support customer success? |

What’s Next?

For more information about product management, sign up for our newsletter. We send out insightful content every week. You can also check out our list of the best product management tools currently available.